Gridcore Drilling Services North QLD

We specialise in providing safety driven, professional and high-quality drilling solutions to Queensland’s energy and commercial industries.

If you’re looking for reliable and experienced drilling contractors in Queensland, contact the Gridcore team today. We’re here to answer your questions and provide solutions for your drilling requirements.

Gridcore Water Bore Drilling North QLD

North QLD Water Bore Drilling Experts with 100% Customer Focus

Specialist water bore drillers providing expert water bore drilling services for businesses, farms, and industrial sites across North QLD

At Gridcore, we understand the critical need for a dependable water source, and our team of experienced drillers is equipped to deliver a tailored solution for your specific requirements.

Gridcore Water Bore Drilling Services

Our services include but are not limited to:

- Sub Artesian and Artesian Water Bores and Wells

- Mine site water supply and dewatering bores

- Mud Rotary, Rotary Air and Air Hammer drilling

- Test Holing

- Breakthrough holes for dewatering

- Monitoring Bores, geotechnical drilling and recovery bores

- Bore Cleans, Bore Decommissioning

- Mine Site Closure Programs

Gridcore Water Bore Drilling Services

Our services include but are not limited to:

- Sub Artesian and Artesian Water Bores and Wells

- Mine site water supply and dewatering bores

- Mud Rotary, Rotary Air and Air Hammer drilling

- Test Holing

- Breakthrough holes for dewatering

- Monitoring Bores, geotechnical drilling and recovery bores

- Bore Cleans, Bore Decommissioning

- Mine Site Closure Programs

The Benefits of Water Bore Drilling:

We understand that every property and water requirement is unique.

- Reliable and Cost-Effective Water Source: Water bores provide a dependable long-term water supply, reducing reliance on municipal or inconsistent surface water sources. This can lead to significant cost savings in the long run.

- Improved Sustainability: By utilising groundwater resources, you can lessen the dependence on council provided water supplies.

- Independence: Having your own water bore provides greater independence and control over your water usage.

Our team of experienced and qualified water bore drillers will work closely with you to understand your specific needs, check out your site and recommend the most appropriate bore depth, diameter, and pump capacity.

We are committed to clear communication throughout the process, keeping you informed and involved at all times.

Gridcore Water Bore Drilling Process:

Our water bore drilling process is meticulous and efficient. Here's a simplified breakdown:

- Site evaluation: Our team will visit your location to assess factors like ground conditions, water table depth, and potential bore yield.

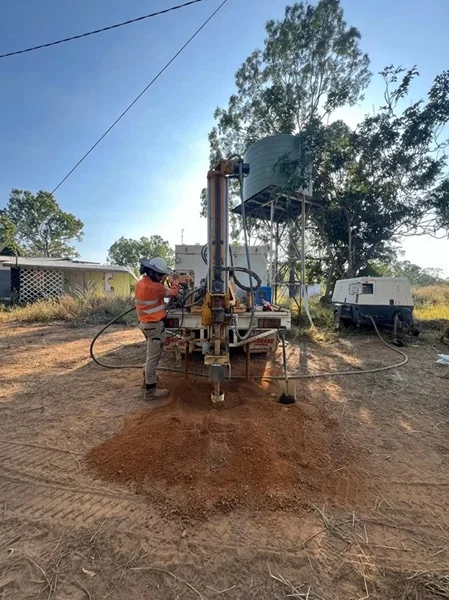

- Borehole drilling: Using state-of-the-art drilling rigs, we create a borehole to the designated depth.

- Bore casing and grouting: The borehole is lined with a casing to prevent contamination and ensure structural integrity. Grout is applied to further stabilise the casing within the surrounding ground.

- Bore development: This process removes any drilling debris and helps optimise water flow from the aquifer.

- Pump installation: A submersible pump is installed to extract water from the bore.

- Water testing: We recommend water testing to ensure the quality of the bore water meets your specific needs

Water Bore Licences and Permits in Queensland:

Drilling a water bore in Queensland requires a licence

At Gridcore we ensure our licensed drillers keep up to date with all the latest legislative requirements regarding boreholes. We ensure compliance with all relevant regulations set out by the Department of Natural Resources, Mines and Energy (DNRME) and can certainly assist you in obtaining the correct permits.

Gridcore Deep Drill Earthing Services North QLD

Our Deep Drill Earthing Solutions North QLD

We have a demonstrated commitment to supplying complete deep drill earthing solutions

Gridcore has earned a trusted reputation with Ergon Energy and other energy companies throughout the North Queensland region.

We offer services that include trenching, excavation and backfill works on-site through the use of a Hydrovac excavation trailer. All Gridcore vehicles are custom built to handle the roughest conditions and access those hard-to-reach places. This provides us extra flexibility to meet your site requirements.

Hydrovac Excavation

The most cost effective, safe and non-destructive method of excavating a jobsite

Our services include trenching, excavation and backfill works on-site. We use our Hydrovac excavation trailer with the following benefits:

- less time in excavating the required path, and less time in cleaning up once the job has been done

- any underground utilities are easily and safely exposed without the risk of damage, avoiding the risk of disruption to services

- we use a procedure known as Pot-holing, whereby the Hydrovac is used to excavate the initial 2-3 metres of the drill path to ensure no services are present prior to the deep drill process

- The Hydrovac system works by combining high pressure water with a large vacuum in order to cut a path in the ground

- As high-pressure water cuts its way through the ground, the vacuum is trailing behind syphoning the leftover slurry into a spoil tank

- the process exposes underground utilities & obstructions, without damage any of the components, such as conduits, pipes & cables

High And Low Voltage Earthing

Gridcore provides safe, professional deep drill earthing solutions for all variations of electrical and communications networks.

This includes installation, repairs, testing and commissioning of new and existing earthing systems across North Queensland.

We supply deep drill earthing solutions for the following earthing systems and equipment, and will customise our methods to suit your standards and requirements:

- Low Voltage MEN (Multiple Earthed Neutral) systems

- Low/High Voltage CMEN (Common Multiple Earthed Neutral) systems

- High Voltage SWER (Single Wire Earth Return) systems

- High voltage switchgear earthing and earth mats

- Pad mounted transformer earth mats

- Substation earth mat systems

- High and low voltage earthing for transformers

- Mobile substation units (Pegasus) earth mat systems

- Metallic structure earth bonding

- Transformer remote earthing

System Earthing is critical to any electrical installation

Gridcore understands the importance of Low Impedance Earthing Systems and and the consequences of poor earthing.

It’s our focus to ensure we supply a quality end to end service that you can rely on. As part of our commitment to safety we also provide our own fully equipped hydrovac excavation service. This is dispatched prior to drilling, to ensure the drill path is clear and safe. We supply a seamless end to end service, across the whole of North Queensland. This starts with the initial contact, followed by quoting, and scoping the job site.

Before You Dig Australia Policy

Before drilling starts, a “Before You Dig Australia” site investigation is carried out.

This is followed by a Hydrovac Excavation of the drill path, to ensure there are no services or obstructions in the drill path. Once the path has been cleared, the drilling rig is put to work. On completion of drilling to the required depth, the earth electrode and attached copper wire is pushed to the base of the hole. We then backfill using bentonite to decrease the resistivity of the soil around the earthing components. This increases the effectiveness of the new earth. Earth testing is then conducted by a licensed electrician, with the results being recorded on a test sheet for customer reference.

Gridcore Fleet and Equipment

We have custom built equipment to provide the best outcomes for your deep drill earthing needs, built in Australia to the highest engineered standards.

Our drilling equipment has been built in Australia to the highest engineered standards.This means we are able to drill in all types of soils and underground conditions including rock and clay.

Our drill rig is fitted with a two speed rotation head. This creates the versatility to use either Auger or Coring techniques, depending on the soil conditions………..